Many businesses have to deal with the problem of buying product in one unit and selling it in another. It’s one of those items of ERP functionality that you don’t think of – unless you are in a business where it’s a necessity.

The term for using different units is called Multiple Units of Measure, a feature that SYSPRO has supported for some time. A unit of measure (UOM) describes how the quantity of an item is tracked and managed; common units are ‘each’, ‘piece’, ‘pack’, ‘metre’, ‘gallon’, ‘pallet’. Providing this functionality allows customers in industries like food and pharmaceuticals to manage complex inventories. Typically, items can be bought, made, stored, costed, transported and sold in different UOMs, and a business needs to have a standard for converting one UOM to another.

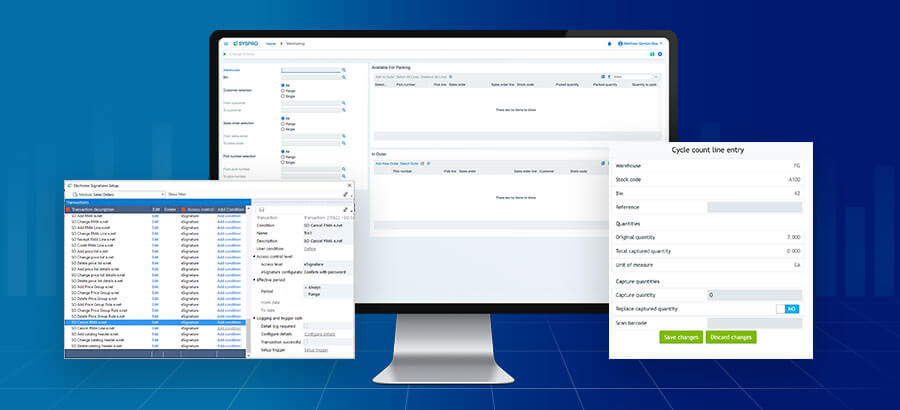

In SYSPRO the standard unit is the stocking unit of measure, but other UOMs are available.

- Inventory unit of measure: for stocked items

- Cost unit of measure : used for the inventory cost of the item

- Manufacturing unit of measure: a unit used to handle manufactured item and component quantities in the production process

- There are also two alternative units of measure for sales and purchasing quantities

What are some of the use cases for multiple units of measure?

- The simplest use case is for food producers who have the product in different sized containers, e.g., beer sold in single bottles (each), pack of 6, case. Other manufacturing systems require that each different size is a different SKU (stock keeping unit), SYSPRO allows the inventory item to be the primary product, and packaging variations to be a secondary consideration.

- A second use case involves ‘catch weight’. This is where producers or distributors sell a product by weight and the individual product’s weight can vary – this is different to standard weight. SYSPRO allows you to sell by unit count and catch weight, so enabling a more accurate pricing of product. An example is a business selling chicken, where each chicken has to be sold by its actual weight rather than a fixed price.

- A third use case is for businesses that buy and sell in different units. For example, a steel company that buys steel in sheets, but cuts and delivers to customers as pieces of steel; the same product but sold differently to the way it was bought.

With multiple units of measure, an organization can use the unit of measure for each inventory item as the business wants it. The unit of measure may vary according to who uses it, e.g. in engineering, production may want to measure steel output in metres, but warehousing wants to count it in rolls, and accounting cost it by tonnes.

Being able to provide a customer with a product in the quantity and packaging they ordered is a measure of perfect order fulfilment, and being able to handle multiple units of measure enables that.

Have you heard of any unusual units of measure? Do you have a good story about using different units of measure to satisfy a customer order? We would love to hear about it.