Are you a supply chain guy or gal focusing end-to-end rather than on one area like distribution or manufacturing? Or did you start in manufacturing caring only what happens in your plant and focusing with a narrower perspective? If so how does this affect our application of Business IT like ERP?

Lone Manufacturing Operation

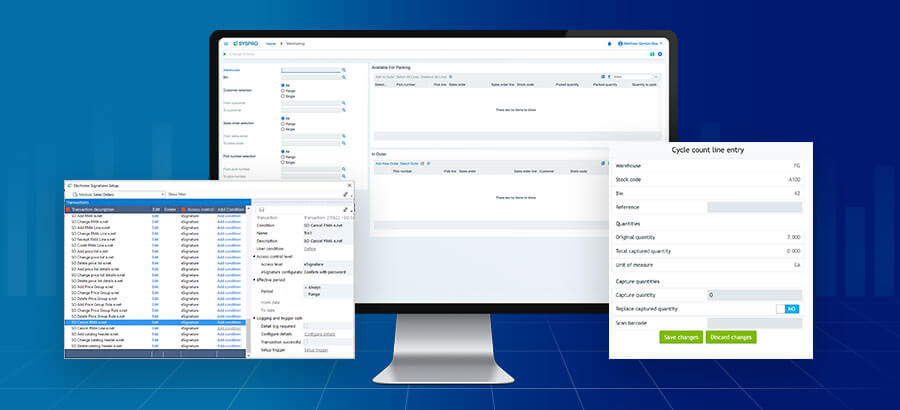

Let’s start in the metal fabrication business making pumps to stock and to order where our focus used to be keeping all machines and operators busy rather than scheduling what’s actually needed. But then we find SYSPRO using BOMs to define the structure of products and Requirements Planning (MRP) to plan material procurement and appropriate stock levels, suggesting when/what to order. Finally Requirements Planning again (MRPII this time) to schedule and manage production operations.

Once used to MRPII scheduling – with infinite capacity – we mature to using a finite scheduling tool to optimize the sequence of operations, maybe even using the Theory of Constraints (TOC) to manage bottlenecks effectively first – leaving some machines idle intentionally for a change. Oh and Inventory Optimization to get the best use of working capital of course.

A narrower and narrower focus – and still inside one factory.

Running Your Own Supply Chain

Now we’re in the food business making canned food in one plant, processed meats in others, and spice packs in another. All plants used to run independently but now we want to run a slick supply chain because that’s what our retail customers need. As some materials and packaging suppliers are shared by all plants and we use logistics service providers (LSPs) for inbound, in-between and outbound logistics, we’re a supply chain operation.

First we master plan our supply chain to synchronize end-to-end to achieve a weekly hi-level plan for supply, manufacture and distribution at the different plants/warehouses. Moving to execution, we use MRP again at each plant focusing on inventory management – in particular warehouse processing – to handle finished goods. We also used more of SYSPRO’s functionality with multiple bins to help with batch traceability and picking.

Once used to this and maturing we add a more powerful Network Optimizer to plan the best throughput through our supply chain (end-to-end). And this will mean we don’t always go flat-out everywhere keeping operators busy – unless it’s to the network plan. This tool creates alerts to get all network partners (our operations, suppliers and LSPs) to collaborate to get back on plan or warn them where we deviate or can’t meet it.

Another IT move is to centralize warehouses to one DC. Introducing advanced WMS that optimizes storage and flow through the warehouse – rather than just finding a bin to put stock in. Then we get into transport loading/scheduling and even more sophisticated track and trace.

So while there are many IT tools, there are different strokes for different folks. The trick is to get used to the initial challenge of ERP and then let your SYSPRO IT grow as your process matures and your business needs grow.