I love my job. Every day I get the opportunity to visit and walk through a new factory or operation, being exposed to the unique challenges faced by each and every-one of our customers. In the last two years it became even clearer that today’s manufacturer must understand the need to be agile, flexible and responsive, and that requires a software solution that gives them leverage to use whatever production methods are appropriate, including the partial or complete outsourcing of manufacturing.

The use of third-party manufacturers varies greatly from industry to industry, and from company to company. A company may choose to outsource all production or to outsource increased demand around peak sales times that require a specific piece of equipment or special handling.

Across Africa, many small and medium manufacturers rely on third parties for many vital operations, as they do not have the capital, cash flow or appetite to invest in new or additional machinery. Outsourcing can even include the warehousing and fulfilment of goods to a third-party logistics partner.

Outsourced manufacturing challenges

This third-party outsourcing process is not perfect and does come with various risks for manufacturers. As they have bought and own the necessary raw materials or components, then send them to a third party to assemble, they do not have full visibility and control of the process and face significant liability.

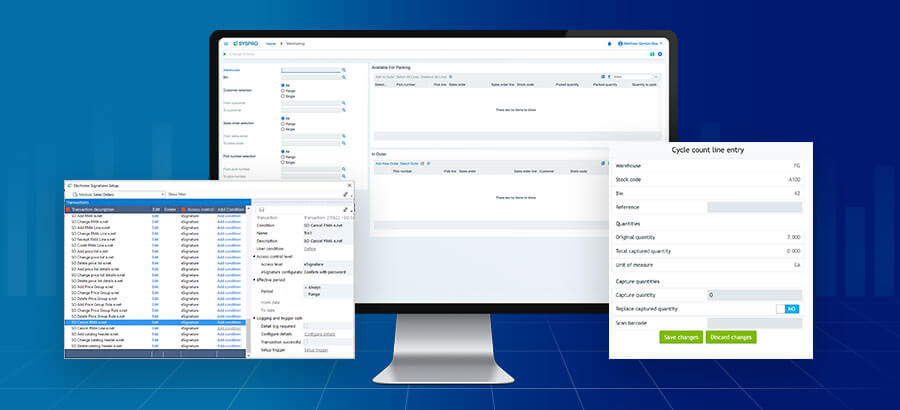

Standardizing manufacturing processes, both in-house and outsourced, increases efficiency and reduces overhead costs. In this digital age, software is used to standardize your third-party manufacturers and you can take advantage of the benefits offered by outsourcing while minimizing risks.

In addition to standardization, the software must provide complete visibility through the manufacturing chain – back to suppliers, along the production process, and up to customers. Inventory visibility remains crucial and gets more difficult as business processes get more complex – you add more manufacturing locations, warehouses and sales channels. Without inventory visibility, demand planning and forecasting are left to chance, leaving you with too much inventory, or not enough.

Managing outsourcing with ERP

ERP software provides a fully integrated solution with a comprehensive set of tools to help manufacturers plan, execute and control production in discrete, job shop, process or mixed-mode manufacturing environments. This empowers job shop operators to manage the challenges like these inherent in the custom-design and order-fulfilment process. With an end-to-end software platform built to meet job shop needs, you can easily connect your operations across multiple third parties, from product design through production to finance and accounting, gaining remarkable efficiencies.

As manufacturing continues to shift and change, with businesses under increasing pressure not only to maintain a competitive edge but also to innovate, manufacturers must utilize the technology at their disposal in order navigate the challenges they face.