Picture a manufacturing plant. Are you seeing machines and robots, tools and people powering away to bring the best possible product to you? Now, think about the skills required to do all this? Are you thinking digital fluency, critical thinking and collaboration? If not, you should be.

The skills gap in manufacturing

Manufacturing is an industry of skills. Every factory runs on the back of hundreds of specialized skills, some of which take a long time to master. According to a 2023 World Economic Forum report, adoption of technology will remain a key driver of business transformation over the next five years. As a result of this transformation, employers estimate that 44% of workers’ skills will be disrupted in the next five years.

The WEF report also noted that organizations’ plans to increase automation had slowed down. But while employers have revised down their expectations for automation, a new set of skills will be needed, some of which were not even considered three years ago.

New skills requirements in manufacturing

Companies are investing in learning and on-the-job training as the most common workforce strategy to deliver business goals. The key skills that manufacturers are looking for are:

- analytical and creative thinking;

- digital fluency — how to understand and apply technology effectively and ethically;

- data fluency — how to interpret data and effectively communicate ideas;

- proficiency — take less time to perform an operation with less supervision;

- ability to communicate with others;

- improved self-management and resilience;

- how to use technology to improve collaboration;

- understanding how manufacturing processes can be more sustainable.

Challenges to skills development in manufacturing

The WEF reports that the challenge for manufacturers is that while 60% of workers will require training before 2027, only 50% have access to adequate training opportunities.

Recent research has highlighted some concerning issues around skills development. A McKinsey report on employers’ preparedness noted that:

- 25% of employers lacked a clear understanding of the impact that future automation and digitization would have on skill requirements;

- 25% lacked the tools or the knowledge to quantify the business case to reskill their workforces;

- 30% considered that their HR infrastructure did not have the capability to execute a strategy designed to address emerging skills.

On the workforce side, a PwC survey reported that while 36% of employees agree that the skills needed in their jobs will change over the next five years, only 43% have a clear sense of how the skills will change. An issue that is more concerning is that only 15% of workers whose jobs do not require specialized training see that the skills required to do their jobs will change in the next five years. It is the skilled workforce who seem to be better prepared for new skills requirements.

Employers need to anticipate and understand these issues.

How learning technology is changing the training environment

Advancements in learning technology are allowing employees to “learn in the flow of work” — making learning more accessible in the workplace. This can help remove some of the barriers between work and learning and is an effective way to deliver training whilst reducing disruption to employees’ regular work.

With increased online learning now possible, learning is more accessible and also more sustainable.

Modern learning tools can be configured to suit different learning styles, whether auditory or visual styles, and can enable micro-learning — learning in small chunks that reduces the time and still achieves the training goal.

Like many other aspects of business, AI also has a part to play in training and education. With generative AI tools, the need for some formalized learning can be reduced as the full answer to some questions can be found online.

Executives’ responsibilities to improve manufacturing training

The skills shortage in manufacturing is not going to go away. If anything, it is going to get worse unless manufacturing executives understand new issues and requirements around training. They need to embrace all the options open to them to ensure the workforce has the time, resources and encouragement to upgrade their skills and learn new ones.

So when asked to picture a manufacturing plant, they’re seeing a team of skilled, flourishing people.

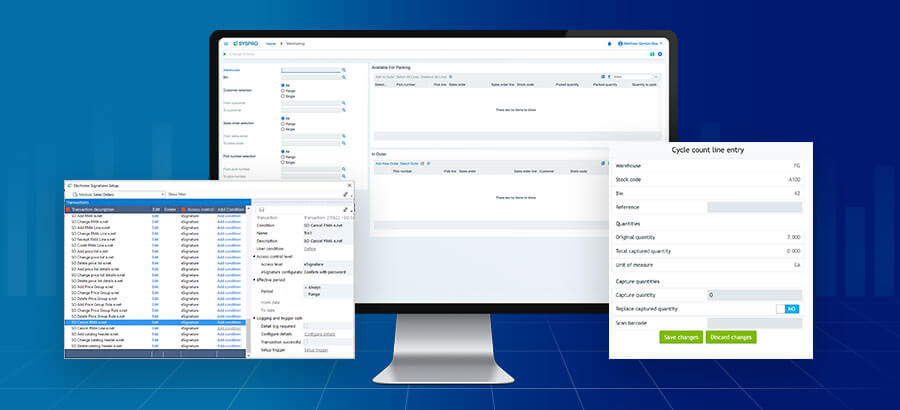

See the future of manufacturing education on SYSPRO LearnIt Online