Like in so many other industries during the pandemic, technology is having an impact on job shops. Final products are produced in small batches of varying quantities, and because they are custom products they are not usually standardized. This has advantages in that sales discounts and finished good inventory are reduced, and stock obsolescence can be managed more easily. However, there are challenges that come with the MTO approach. The main manufacturing challenge for job shops is scheduling, and from that flows other challenges in sales, inventory and accounting.

How can technology help address the challenges job shops encounter?

Job Shop Challenges

Production

A shop floor supervisor in a job shop has to deal with several issues.

- Rush jobs and customer change orders mean production planning and scheduling is done amid uncertainty

- It can be a problem to identify which orders are most likely to be late and therefore how to prioritize jobs

- Some jobs can be relatively straightforward, whilst others are more complex and require re-scheduling of the production flow

- Because jobs are different, machine set up times vary which means shopfloor capacity fluctuates, making it difficult to plan work

- If machines are scheduled poorly, this can lead to production bottlenecks, under-used staff or overtime, excess inventory or shortages, dissatisfied customers and loss of revenue

Estimating and quoting

The sales environment of a job shop has to cope with a wide variety of products but a low volume of them. This poses a problem when developing a standard product and pricing list and so the quality of quotes can vary. Developing consistent and accurate pricing comes from experience and the knowledge is not easily transferable. This is not helped by pricing spreadsheets that often fail to connect costs with prices.

Managing demand

In the job shop environment, the randomness and variability of customer demand creates uncertainty. Many job shops use spreadsheets and email to track customers and keep the sales pipeline filled. This hodgepodge of systems does not help to build a clear picture of leads, prospects, and customers. It can also make it difficult to identify the profitability of different jobs.

Inventory management

A variable production schedule means variable inventory needs. Poor quality information about inventory requirements and supplier capabilities means problems for warehouse managers. If the required materials are not available at the right time, in the required quantities, this can result in production delays and cost overruns.

Accounting

It can be difficult to run reliable accounts if processes and data are not consistent. The challenge is to make the order-to-delivery and invoice-to-cash processes repeatable. But too often job shops spend time entering the same data into different systems, and using different software for different areas of the business. Consequently, working out profitability is difficult. Businesses also struggle to keep supplier prices up-to-date and therefore costings can be inaccurate.

How ERP software can help job shops

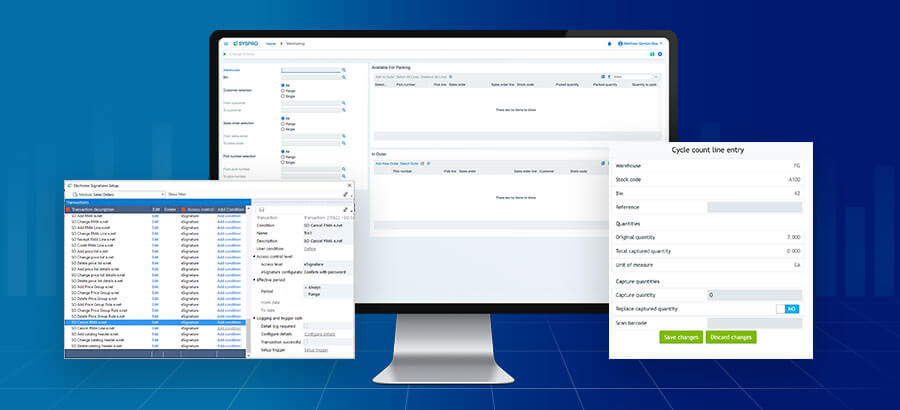

Technology is readily available for job shops to get a 360-degree view of the shop floor, including the various work centers and jobs awaiting assignment. ERP software allows shop floor activities to be integrated with production planning, quotes and sales orders, inventory, purchasing and accounting. Job shops can use an ERP system to break down the silos that separate difficult functions of the business and streamline processes throughout the company.

Scheduling and production management

There are tools within an ERP system to help production staff plan, monitor, and execute jobs with a high degree of flexibility. These tools provide visibility of schedules and material plans, current and future jobs, and resource availability.

A Bill-of Materials (BOM) records the items and processes needed to make a product and provides the basic data for better resource and capacity planning, product costing, and material requirements. The BOM is the foundation on which materials requirements can be established, from which purchasing requisitions are created. It also sets the configurations in which jobs are run. Once these are established, scheduling jobs and machines can be done. From this, planned versus actual work of jobs, machines and other resources can be monitored as work-in-progress.

Monitoring production information should include recording of scrap and re-work so that accurate costs per job and per machine can be determined. There should also be a scheduler to assist in maintaining accurate and up-to-date production schedules and improve co-ordination between work centers to achieve increased productivity and required customer service levels.

Quotes and pricing

A key to having accurate pricing so that correct quotes can be created is knowing what items make up a product. It starts with getting the data from BOMs to provide a solid basis to calculate costs and lead times for quotes.

Instead of using spreadsheets to produce quotes, an ERP system with a quotations module enables estimates to be based on all aspects of a job – material, machine, people. When a quote is approved, the information on the quote can automatically create jobs, purchase orders and sales orders.

Products that job shops sell are highly customized, therefore manufacturers should consider an ERP system that has a product configuration module. This lets non-technical sales staff generate accurate product and pricing specifications for customized products.

Managing demand

By consolidating all customer-related data into a customer relationship management module, both sales staff and executives can get a better picture of prospects and customers. This can enable them to segment and target customers based on criteria such as profitability and frequency of orders.

Inventory and material management

In the dynamic production environment of a job shop, change orders can leave unwanted inventory on the shop floor. Job shops can use their ERP application to create reverse job issues so that if a customer changes an order, material that is no longer required can be returned to stock.

By integrating the warehouse with the factory floor, job shops can get an operations-focused view of inventory, for example, identify low stock levels for forthcoming jobs. When new stock is required, purchase requisitions can quickly be created.

Accounting

For accounting, an integrated ERP system can provide information on the various cost issues that job shops have.

- Approved product design changes can update the contents of BOMs which automatically update costs

- By integrating the production aspects of the business with the accounting function, details of costs for material (as well as scrap), labor costs and machine costs can be gathered and analyzed. This enables the identification of exceptions and problems in a much quicker time

- Similarly, valuation of inventory can be easily obtained, at various from warehouse to individual items. By using costing methods such as Standard, LIFO and FIFO, accurate decisions can be made about inventory use, product pricing and profitability.

Why select an ERP system for a job shop

The challenges of running a job shop in today’s market are changing, with customers increasingly expecting online access for placing and checking orders. Running a job shop business to meet changing demands whilst maximizing profitability will mean taking advantage of software systems that help organizations run effective and efficient operations.

A common question is “what is the ROI of an investment in an ERP solution?”. The value of having all the information about the business available in one system is that each department can plan, monitor and report their contribution to the business, and use information to improve. If consistently meeting customer deadlines, accurate scheduling, reduction in scrap and waste materials, a more profitable production process, and accurate costing for quotes and sales orders are important, then the ROI of ERP becomes more evident.