MES vs MOM

The term MES (Manufacturing Execution System) was first used by analysts in the 1990s to describe a category of software that defined a system that tracks and monitors the production of manufactured goods on a factory floor. A decade later the term MOM (Manufacturing Operations Management) replaced MES to refer to a system that was broader in scope.

It is therefore best not to talk about MES vs MOM as both terms describe the technologies that occupy the solution space. Using these two terms gets some people confused. However, it should be noted that certain vendors refer to MES because it is familiar.

MES and MOM in Industry Strategy and the Smart Factory

Many advanced manufacturers have an industry strategy that aligns and supports the overall business strategy and its objectives. This enables the manufacturing function to deliver what the business needs and adjust operational capabilities to become more productive and effective in navigating the market and serving customers.

The concept of the Smart Factory derived from the Fourth Industrial Revolution (4IR) which was coined by the World Economic Forum. Smart factories use IoT-enabled technologies like sensors and smart machines to generate data, often in real-time, to improve information about production processes and help decision-making.

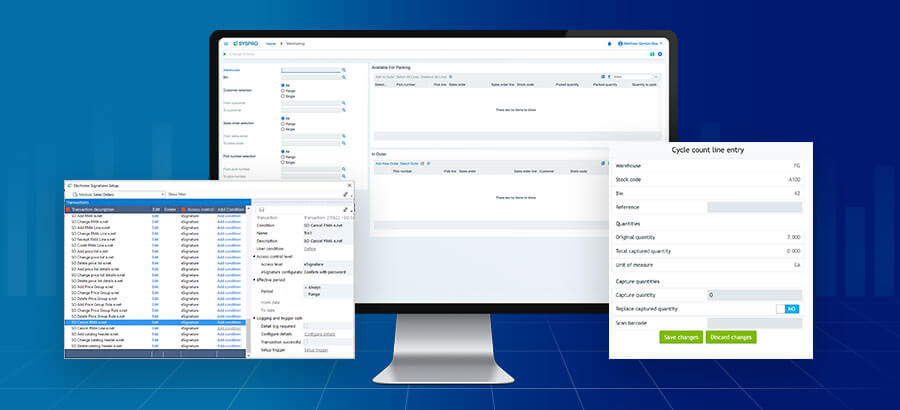

MOM provides the broader functionality required for a Smart Factory, like Advanced Production Scheduling and Quality Management, and includes functionality formerly described as MES, like, automated Shop floor Data Collection (SFDC) enabled by IoT. Together MOM and MES provide the intelligent systems to collect, deliver and analyze production data to empower industry strategy and smart factories.

What is an MES?

A narrow definition of MES is that it serves as a work order–driven, work-in-progress tracking system that captures information from the production floor and manages and monitors production events and reporting. It tracks operations from order release, to manufacturing, to finished goods.

Many early MES systems were purpose-built systems that were often too rigid to adapt to changing business needs. Several early implementations were costly as the implementation process was extremely long. MES therefore earned a reputation as an expensive and risky endeavor that often did not deliver on business goals.

What is MOM?

MOM encompasses a broader scope than MES, covering other aspects of manufacturing operations such as quality management, materials management, and maintenance. MOM provides a unified solution to handle all operations across the manufacturing enterprise.

Unlike MES which focuses solely on the execution of manufacturing processes, MOM provides a broader, integrated perspective of various dimensions of production management in order to achieve operational efficiency and excellence across the manufacturing lifecycle. MOM solutions aim to connect, manage, and optimize complex manufacturing systems and processes.

MOM systems facilitate the digital transformation of manufacturing operations by integrating multiple aspects of manufacturing operations, including production, quality, maintenance, and inventory management, to provide a comprehensive overview and control over manufacturing operations. It uses advanced technologies to enable manufacturers to gain insights into their operations, predict maintenance needs, and improve overall production efficiency.

MES is a subset of MOM. Or you can think of MES vs MOM as the difference between a dinghy and a yacht.

Benefits of using a MOM vs MES

In several areas, the benefits of an MES and a MOM are similar. These include:

- Production optimization

- Recording machine start, stop and downtime

- Event management

- Job assignment

- Parts and component count

Additional benefits of MOM

But a MOM goes further by helping manufacturers to take advantage of 4IR opportunities through the adoption of technologies that provide the digital foundation for the Smart Factory. A MOM is device-agnostic and enables staff to interact with the system from anywhere and anytime. As sensors and smart devices proliferate, this becomes an increasingly important feature.

A MOM has the flexibility and scalability to become a true enterprise application, including features such as:

- Advanced Production Scheduling with live monitoring enabled by 4IR

- Standards-based integration with ERP systems, and with industrial automation technologies

- A standardized manufacturing data model

- Business process management and optimization for manufacturing capabilities

- Monitoring and control of quality standards throughout the entire production process

- Monitoring labour and machine costs

- Traceability of all production materials, components, and finished products

A MOM allows managers and executives to gain visibility over every stage of the manufacturing process, and helps to digitize the factory by reporting real-time information collected from devices and machines. It sends alerts to and from the shop floor that help to improve efficiencies through early intervention and resolve performance-related production issues.

To achieve improvements on the factory floor, a MOM can provide information on overall labour effectiveness (OLE), overall equipment effectiveness (OEE) and total effective equipment performance (TEEP). These are metrics to measure the efficiency of manufacturing, and identify areas for improvement in equipment and operations.

A good MOM system can drive Lean Manufacturing , as well as Six Sigma and Continuous Improvement initiatives.

A MOM system can be applied not just in one plant but also across multiple plants for an enterprise-wide view of production operations. By integrating this information with an ERP system, the result is business-wide visibility and control, as well as the optimization of production activities from customer order to finished goods.

How MOM Improves Manufacturing Operations

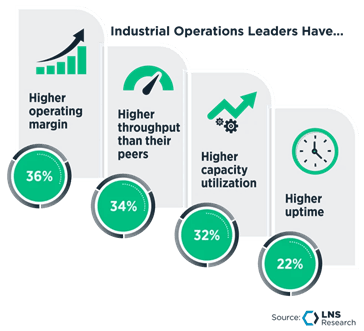

A MOM provides key advantages to manufacturing companies in their industrial operations.

Source: LNS Research.

An MES is a software application that monitors, tracks, documents, and controls the production process on a factory floor. A MOM system helps manufacturers to transform people, processes, and technologies to deliver a significant improvement in productivity. This enables companies to provide innovative products and services, build trust and transparency across the value chain, and offer excellent quality and customer service.

MOM enhances manufacturing by integrating planning, execution (the sole focus of MES), and monitoring into a cohesive system. It streamlines production by providing real-time visibility into operations, optimizing resource use, and reducing downtime. MOM improves quality through better tracking and control and ensures compliance with standards. By connecting the shop floor to enterprise systems, it enables data-driven decisions, ultimately driving higher productivity and responsiveness across manufacturing operations.