In today’s global economy, Australian manufacturers must transition to a more sustainable and ethical business environment if they want to stay profitable. The pandemic has exposed critical supply chain weaknesses, particularly among suppliers with poor workplace health and safety practices. Global calls for greater inclusion and transparency have resulted in organizations with alleged human rights violations throughout their supply chain, or lacking diversity within their workforce, coming under public scrutiny. Increasing regulatory and consumer pressure for climate action has also prompted companies to make a record number of sustainability commitments. These events have highlighted the importance of sustainable, resilient, transparent, and legally compliant supply chains.

Whether you are a large manufacturing company or a small, specialized firm, there is no escaping the fact that regulators, investors, and consumers are increasingly concerned about companies’ environmental, social, and governance (ESG) practices being in line with the standard requirements and expectations.

What is ESG?

Environmental, social, and governance (ESG) criteria are standards for a company’s operations. Like the term sustainability, the criteria are broad guidelines for an organization to do better and be accountable in environmental impact, social responsibility, and organizational governance.

In a manufacturing business, measuring ESG standards comes down to tracking internal and external Environmental, Social, and Corporate Governance standards:

- Environmental practices look at the resources a manufacturer uses, the waste it produces, and the resulting consequences of those activities on the planet. This includes water management, greenhouse gas (GHG) emissions, and the use of dangerous chemicals.

- Social refers to how the organization manages its relationship with internal and external stakeholders. This includes labor relations, employee training and education, reputational issues, and how a business fosters positive relationships within the broader community including suppliers and customers.

- Governance looks at the organization’s internal framework of procedures, practices, and controls. This includes internal processes utilized to govern itself, comply with regulations, conduct external audits, and guide decision-making.

The impact of ESG for manufacturers

With investors and consumers worldwide prioritizing the environment, corporate ethical behavior, social responsibility, and strong governance expectations (including from the suppliers of their goods and services), conducting business without proper consideration for ESG can translate into a financial or environmental cost, harmful social or reputational exposure for a company and financial damage to its bottom line, and ultimately its shareholders.

How can ERP help with supply chain?

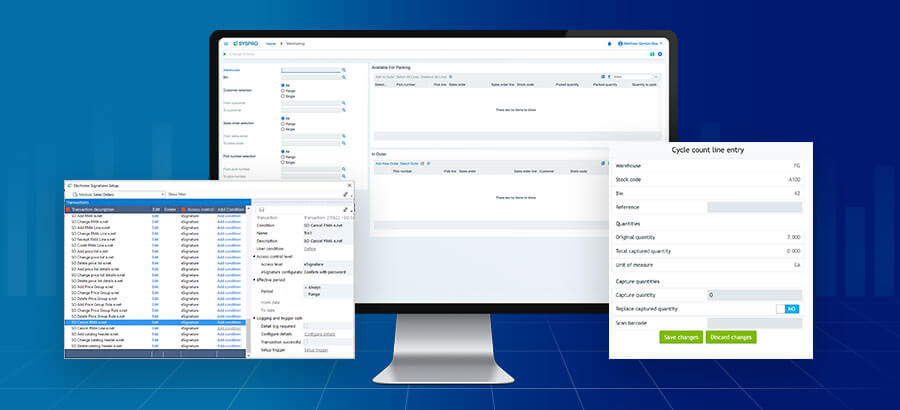

ERP enables organizations with the visibility into relevant data across the business – it allows them to obtain the insights required to comply with regulations, meet stakeholder and customer expectations, cut costs, optimize processes, and ultimately improve overall efficiencies to meet ESG standards.

Technology solutions like Artificial Intelligence (AI), Machine Learning (ML) and Big Data analytics enabled by an ERP system can also assist with managing the environmental impacts. Such technology, for example, can help organizations identify the fastest, cheapest, and most sustainable shipping routes. Using an ERP system manufacturers can make their supply chains more efficient for example tracing every product from raw material to finished product to ensure it’s sustainable while reducing waste. Integrating government, risk and compliance with your ERP platform makes the process of regulatory compliance and reporting so much simpler – and safer. Instead of a siloed approach, strategy, risk, performance, and sustainability are on a centralized platform for a single view. Manufacturers can make informed and better business decisions through accurate real-time data.

Without a centralized ERP system, compliance and visibility can be manual, tedious, and costly, even resulting in penalties. Supply chain visibility leads to many advantages for today’s global and agile businesses. It allows them to reduce complexity, improve communication throughout the organization, stay nimble and keep up with a complex regulatory landscape regarding ethically and sustainably sourced goods.