We are undeniably an industry that loves our acronyms – SCM, IoT, CRM, AI, PSAs. I could go on… Well, over the coming months and years you’re going to be hearing a lot more about a new acronym – DSN, or Digital Supply Networks. While there remains a certain degree of uncertainty around the impact that developments such as robotization, automation, AI and cloud-based technologies will have on the manufacturing industry, there is no doubt that these technologies already have – and will continue – to transform the way digital supply chains function.

Third generation supply networks embedded in a fully digitized industrial new age are our future, so sitting back and waiting for these changes to take place simply isn’t an option. Instead, manufacturers should view these developments as an opportunity to review their business processes, to identify where investment will deliver the most strategic benefits and to futureproof their businesses for the long term.

A glimpse of the future

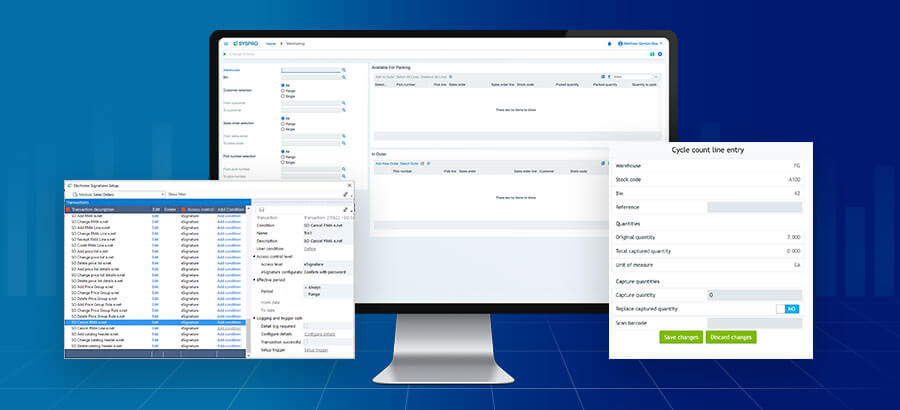

Let’s start by taking a quick look at what defines a Digital Supply Network. Supply chains are incredibly complex and, from our experience, no manufacturer yet operates a supply chain that is fully digitized, with end-to-end visibility and operating in a dynamic network. But the day is fast approaching when everything we do will be driven by technology and we, at SYSPRO, have encountered manufacturers who are already successfully using digital technology at every stage in the supply chain. By engaging Enterprise Resource Planning (ERP) systems to process and harness their data, these companies have enhanced their operational performance and futureproofed their businesses.

So, why is it so important for manufacturers to get the digital supply chain (soon to be network) right? Because when a strong supply chain model is supported by the best technology it renders companies resilient to change in the supply chain. This, in turn, contributes to overall organizational resilience, which is vital in uncertain economic conditions, and also enables companies to be flexible and adaptable to respond to different market conditions, supporting future growth potential and opportunities for manufacturers and the wider supply chain.

First things first

You may already be quite far down the path towards a fully integrated digital supply network, or you may be among the many manufacturing businesses for whom the smart factory and digital supply chain of the future is still many years away. Either way, there’s no denying that there are some very real challenges ahead, particularly for smaller manufacturers, but doing nothing simply isn’t an option.

For those manufacturers that are uncertain about how to begin on this journey towards digital supply networks, then my first piece of advice would be to truly understand your business processes. My last blog goes into this in more detail, but in short, an in-depth knowledge of business processes is essential to an effective implementation of ERP and other digital technologies.

The benefits of benchmarking

Benchmarking is also absolutely key. You need to focus on your key business drivers – the processes that underpin the success of your company. Then you need to decide who to benchmark against. At SYSPRO we would always recommend looking at businesses of a similar size and with similar objectives, but also looking at businesses from different sectors who excel in areas you want to excel in. Look at strategic objectives of your benchmarking partners – what gives them the edge?

It is also vital to look at the mechanics of your business and assess the efficiency of your processes. Reviewing your resource allocation will enable you to determine if you’re putting your resources into the same areas as your benchmarking partners. And, by comparing your costs against industry norms you will be able to highlight areas where your costs are higher than the average, potentially identifying ways to make savings. By calculating sales per employee you can measure productivity and efficiency, and if you work out your profit margins you will be able to understand how efficient your production processes are.

But remember, not everything is measurable in monetary terms: customer service standards can be a deal breaker when a number of businesses offer similar products or services. Take a good look at your returning customers, the number of complaints you receive and the time it takes to fulfil an order. Make customer service a priority if you want to stand out from the competition.

Nowadays, with salary surveys and information on industry financial ratios widely available online, it’s possible to obtain benchmark information without having to approach an external benchmarking partner.