There are good surprises and there are bad surprises – like discovering that, somewhere in your food and beverage manufacturing business, there are serious gaps that are draining your bottom line. Even worse, you don’t always realize it until the damage is already done.

Sometimes the culprit is a direct cost, like raw materials purchase, labor, and shipping – and these may be easier to spot on your balance sheets. But there are indirect costs as well, like the administrative and operational costs it takes to run your business, which often gets lumped together as “overhead” expenses without being tracked or allocated properly.

If you want to maximize your profitability, the trick is to identify those costs – direct and indirect – and create strategies to plug the gaps and stop the drain.

The 9 most common hidden costs that drain profitability

Knowing where to look for hidden costs and unoptimized processes is your greatest weapon in the battle against profitability loss. In most cases, I find gaps occur in one or more of these nine areas within food and beverage manufacturing businesses.

1. Pricing New Products

This may seem like a relatively simple task in theory, but it’s tougher in practice when you don’t update the changing cost of raw materials in your systems or associate them with specific production batches. Combine that with vague production costing where time and resources needed for typical operations like line changeovers, startup, setup, and teardown aren’t taken into consideration, and it’s easy to see where inaccuracies in pricing creep in.

2. Production

Think of all the extra costs your business absorbs from your production lines that are rarely measured or allocated to a specific product’s cost:

- Overtime: You may fall behind on the line, but still have to finish off today’s batch, which means keeping staff and equipment running longer than planned.

- Rework: If there were defects in a batch – almost always in packaging – there’s the additional cost of additional packaging, labour and paperwork to process to account for.

- Scrap: We all know unexpected things happen during production like equipment faults or product jams resulting in product winding up on the floor. That scrapped product is lost profit.

- Lack of automation: If you rely on manual processes and paperwork for data capture instead of automation, you’re spending more on recurring labour for every batch you produce and almost assuring the introduction of data entry errors which will require even more work to correct – if they are even discovered.

3. Business Promotion

After you crunch the numbers, which sales and marketing tactics are truly effective? Sales reps offering discounts may win more business and give you the sense that your sales are booming, but it’s at the cost of reducing your margins – a cost not often measured. Marketing campaigns can be particularly resource-heavy, with direct costs in advertising, media and image licensing, and indirect costs via the time and resources it takes to create content. Tradeshow promotions often seem like an effective way to win new customers, but they rarely break even, much less turn a profit, once you account for the cost of implementation and administration they require to run.

4. Real Purchasing Costs

Purchasers aren’t always given enough lead time or visibility into channel and demand to meet production timelines. That can force them into a reactive buying mode often resulting in paying a premium price or expedited shipping charges. Under crunched timelines, they can’t properly evaluate vendor options, meaning they tend to focus on price alone, missing other important considerations like whether that vendor tends to deliver on time, or whether they’re prone to quality issues.

Quantity matters too. If Purchasing orders too much stock, you will need to consider the carrying cost of extra inventory in your warehouse. Worse, and almost never accounted for, is the fact that as many raw materials age their quality degrades which can affect the quality of your finished goods in turn negatively affecting your brand. If the insufficient stock is purchased, production can grind to a halt when supply runs out (and the rush begins anew as they try to get more stock in, fast).

5. Packaging

Packaging is typically one of the most expensive components in production. It’s also one of the hardest to balance given the trade-off between pricing and volume. You will generally get a better price ordering a large amount of packaging at once, but if there is a design or spec change, that stock will go to waste. Ordering in smaller batches offsets some of those risks, but it introduces new ones like running short on inventory, resulting in last-minute rush orders that can cost a fortune to deliver. You will also need to consider the administrative costs associated with packaging, like the design and artwork, and storage while it’s sitting unused.

6. Warehousing

Warehousing processes run the gamut from how you keep tabs of your inventory (is it done manually on paper forms?) to how you manage expiration dates (do you often throw out or heavily discount old stock because pickers choose the newest?) to where you keep your on-the-floor knowledge (only ‘Bob’ knows where everything is). There’s a lot of room for error – and unexpected added costs – if they aren’t tightened up or even automated.

7. Logistics

Logistics is the second-largest component of manufacturer cost, and those costs can unexpectedly increase due to issues like customers charging fines for missed delivery times or fluctuating fuel prices. The way you plan your route and fill your trailers makes an impact too. Often rarely accounted for is that you are still paying for the driver, fuel, and wear and tear for those returning empty trucks. Unfortunately, customers rarely accept additional fees or price increases and you are expected to simply absorb these costs on already slim margins.

8. Quality

There’s one thing more important than what you make: it’s how you make it. Quality needs to be top-of-mind in the food and beverage industry not only to protect your brand in the eyes of the consumer, but you must also adhere to the guidelines and requirements of governing bodies like the CFIA and the FDA. If your quality management system is based on running product measurements and incident reports via manual processes on pen and paper, spreadsheets or a combination of both – you make it harder and more time-consuming to share information with all of your stakeholders and introduce more opportunities for manual error throughout the reporting process. Never mind the cost of physically storing that paperwork in boxes, sometimes left unchecked for years.

9. Traceability

The cost of a recall goes far beyond damage to your brand. So what’s your plan to control costs in the event of a recall? It should start with a strong traceability system designed to mitigate risk before a recall ever happens. If your information is written on a form and stored away in a box with hundreds of other forms, someone will eventually need to search through all of those files. If there are inaccuracies or fields that were never filled in, someone needs to find the right answers (in some cases, this can take months). Without the full details at hand in a timely manner, you will be forced to recall more of your product than you potentially need to. That’s time, energy and money you could have saved with a system that tracks all your materials throughout your manufacturing process in just a few clicks.

You can’t fix what you can’t see

There’s no single solution for all of these issues, but I can recommend a few approaches to help you find what works best for your business:

- The 80-20 rule: Focus on the highest-impact areas where you can make a change.

What are your strengths and your weaknesses? Do you fall short on procurement, production, promotions or freight? By looking through your data, you’ll be able to pinpoint where improvements can pay off most.

- Standardize processes and operating procedures: If everyone on your team knows

what they’re supposed to be doing each day, and executes on those expectations reliably, you can feel more confident about repeating your successes. Do not assume that because you had a meeting or wrote an email a month ago things have not changed. Food and Beverage companies have one of the highest plant worker turnovers of any industry. Ensure there is clear, regular and, most importantly, two-way communication between management, supervisors and workers. Regular plant “walkabouts” by production management should be the norm. When things do go wrong, standardized processes make it faster and easier to pinpoint the weak spots and get them resolved quickly.

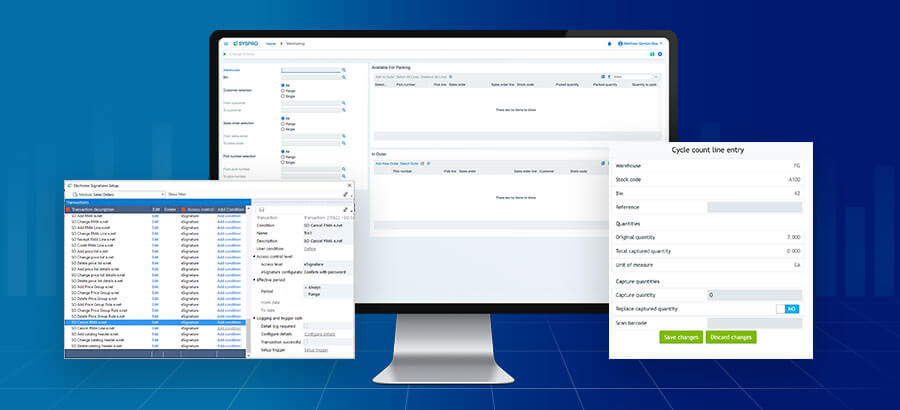

- Implement technology. An Enterprise Resource Planning (ERP) system, for example, can electronically record, centrally store and analyze information from all areas of your business – including your production line – and deliver it in real time where it’s needed most to make better decisions. Not only does this reduce the errors associated with manual systems that come with multiple data entry or trying to decipher someone’s handwriting (Is that 2 or a 5?), but it also saves on time when you need to find that data later on.

Finally, automate production where you can. This does not need to be a large investment all at once. Even sensors that can cover basic, repetitive and error-prone tasks like weighing and counting, can make a big impact.

In short, standardizing and automating processes, capturing data electronically and implementing an ERP system that centralizes and shares information in real time across all departments will give you the visibility to where you are making and more importantly losing money. You can now use this information to make progressive changes and accurately measure the impact.